Wiring diagram cooling fan vaz 2107

Today we’ll talk about why the VAZ 2107 fan (injector and carburetor) does not turn on. A little earlier we figured out how to improve the engine cooling system. The whole procedure is simple and does not require much knowledge. But no less urgent problem - the fan refuses to turn on in a timely manner. We will try to find out why this is happening.

Carburetor sevens

In these cars, the control system for turning on the electric fan is very simple. It can even be called analog. The whole chain consists in the simplest form of the following elements:

- Electric fan motor.

- Inclusion sensor.

- Wiring.

Everything, nothing else, you need to look for damage only in these parts of the structure. In 70% of cases, the sensor fails, in 5% of the electric fan, in 20% the wiring is to blame.

Advice!To diagnose a car, I advise you to use a rather cheap solution: - set it once and always use it.

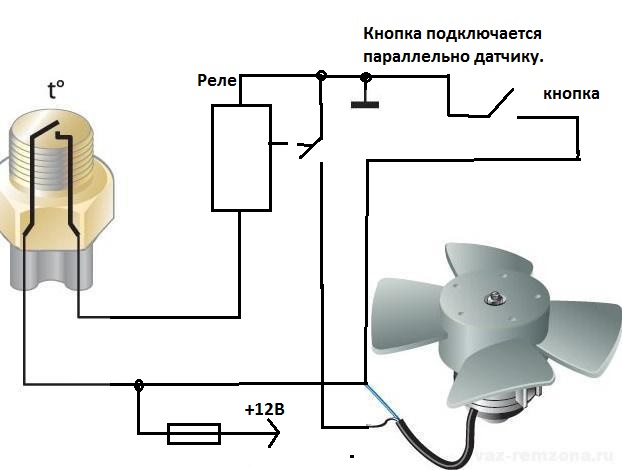

But in some cars, a slightly more advanced circuit is used, in which an electromagnetic relay is included. With its help it turns out to remove high currents from the sensor. This increases the resource of the device.

Some drivers who are not accustomed to trust automation, install the usual button parallel to the sensor (and sometimes instead). Such a scheme has the right to exist, but the driver himself must be extremely careful in order to notice the temperature rise in time and turn on the electric fan.

Troubleshooting algorithm

If your cooling VAZ 2107 (carburetor) does not work, you must perform the following steps:

- Switch off engine and switch on ignition.

- Use a flat-blade screwdriver to close the terminals of the fan enable sensor. Please note that all control is mass. If the fan turns on, the sensor is defective. If it does not work, then the reason lies deeper.

- Disconnect the shoe from the electric fan and directly apply battery power. A rotating rotor indicates that the engine is running. If the electric fan does not work even so, you have to think about replacing it.

- If the fan and the sensor are working, check the electromagnetic relay (if available in the circuit).

- The wires are last checked. Very often oxidation occurs at the junction with the car body. And sometimes a banal cliff happens at all.

The same algorithm can be partially applied to cars on which an injector is installed.

But to compare and evaluate the difference, it is worth considering such machines.

Injection motors

Here, everything is somewhat more complicated, since the following devices are responsible for the operation of the radiator electric motor:

- Electronic control unit.

- Coolant temperature sensor.

- Electromagnetic relay.

The reason why the electric fan may not work (or often turn on too much) lies in one of these nodes. Of course, the engine turns on too often if the radiator cells on the outside or inside are very dirty, if there are air jams. But it does not turn on due to the presence of breakdowns in the control system.

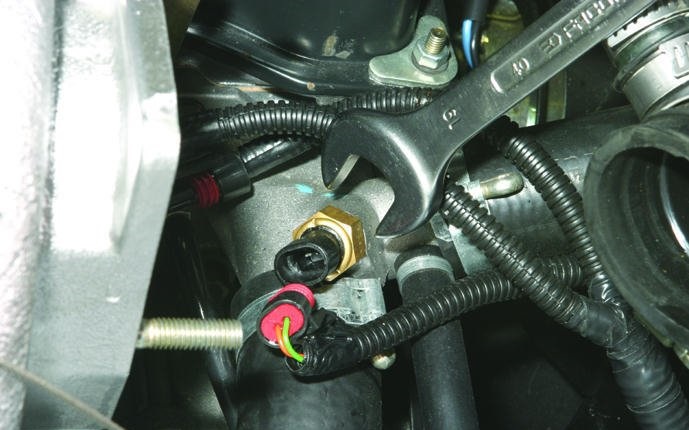

So, you need to find a temperature sensor for diagnostics. It is located in one of the pipes of the engine cooling system of the VAZ 2107. If you look at the engine from above, you will find it under the pipe that connects the fuel rail to the throttle. To test it, disconnect the terminal and measure the resistance between the center terminal and ground. At a temperature of 20 degrees, the resistance should be about 3.5 kOhm. If the temperature is close to 90 degrees, then the resistance will be of the order of 0.25 kOhm.

If there is no resistance, or it differs significantly from the above values, then obviously there is a sensor malfunction, it is impossible to repair it. The price of the new one will be approximately 100-200 rubles (depending on the seller’s appetite). But if the sensor is in good condition, and the electric fan does not work, then you need to check its electric motor and power relay. If no problems are found, carry out a wiring diagnosis.

This article will describe in detail about the forced fan VAZ 2107. Two types of this design can be distinguished - electrical and mechanical. Any owner of the seven begins to regret that in the summer, in a traffic jam, the fan switch sensor suddenly fails. After such an event, as a rule, they begin to think about improving the design. And there are several ways to make an upgrade.

Method one - forced cooling of a mechanical type

Perhaps you can call it that. Remember the first VAZ 2101-2107 cars in which electric fans were not used. In them, radiator blowing occurred due to the impeller screwed to the pump rotor. The exact same fan can be installed on the VAZ 2107 injector. The design of the cooling system is not much different.

But you need to immediately say about some features of this design. The fact is that even in winter the radiator will be blown by a stream of air. This reduces the temperature of the engine, so it can be quite cool inside. In summer it’s good - the motor is always cooled, the fan is constantly running, the antifreeze does not boil.

But make two more small improvements and summer operation will be just a fairy tale:

- Place a plastic diffuser that directs the airflow into the radiator cells.

- The upper part of the radiator must be installed a little closer to the impeller blades. Fasteners to produce small strips of hard metal. Try to make sure that the distance from the surface of the radiator to the impeller is in the range of 2-4 cm.

These small tricks will help you improve the cooling of the VAZ 2107. The price of the question is literally miserable - no more than 80 rubles (this is how much the impeller costs).

The second method is electric

If you have a new machine, an injector and an electric fan are installed, is it worth it to spoil it with a forced impeller? It would be somewhat more reasonable to leave the electric fan, but to make a backup method of switching on with the button. In the store, purchase several items and materials:

- New sensor (if the old one has become unusable).

- Solenoid relay with normally open contacts.

- Red wire with a cross section of 0.75 square meters. mm

- A button for installation in the dashboard of the VAZ 2107 (preferably with a backlight).

- Shrink insulation.

- Sockets like "mother" and block for the relay.

The connection diagram is shown in the photo. First of all, turn off the fan and change the sensor to turn it on. Then assemble the circuit.

Please note that new cars use sensors capable of switching very high currents. But, despite this, they still burn. Sharp loads still quickly disable him. What to do? There is only one way out - to reduce the current at the sensor terminals. To do this, enter the electromagnetic relay into the circuit. Now the chance of sensor failure is reduced. But the chance of failure of the relay becomes higher. True, it will be easier to change it.

Install the forced fan button in the dashboard and stretch two wires from it - one can be connected to the ground immediately, and the second to the sensor output. It turns out that your button and sensor contacts are connected in parallel. Therefore, if the sensor fails, you can turn on the electromagnetic relay with the button.

The third way - perfect fans

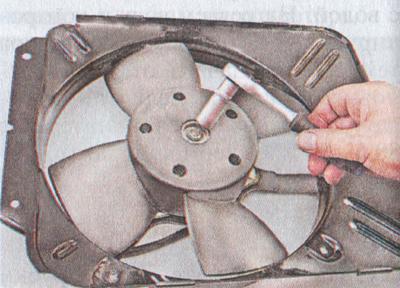

To improve the cooling of the VAZ 2107, you can use more modern ones instead of the standard electric fan. Perfectly fit those that put on cars models "Kalina", "Priora". An electric fan with eight blades will work especially well. The air flow from it will be much stronger, therefore, the radiator cells will cool faster.

An electric fan is provided on parts of cars for blowing the radiator of the air cooling system. It turns on when the 37101B sensor-switch is installed, which is installed in the lower part of the right radiator tank. Previously, power was supplied to the fan motor through a relay. In this case, the temperature sensor TM-108 was used. Currently, the electric fan circuit is simplified and the electric motor is powered directly through the sensor-switch contacts. The sensor is non-separable - in case of a malfunction it must be replaced.

| fig. one |

Fig. 1. Engine Cooling Fan Motor Wiring Diagram

Technical data of electric fan and sensor 37101B (TM-108).

|

Rated shaft speed electric motor with an impeller, min-1 |

|

|

Electric motor current consumption, A |

|

|

Closing temperature of the sensor contacts, ° C |

|

|

Sensor contact opening temperature, ° C |

Electric motor ME-272 (or similar) direct current with excitation from permanent magnets. Installed in a casing mounted on radiator brackets. During operation, the electric motor does not require maintenance, the faulty one must be replaced.

To check the fan motor, we supply 12V voltage from the battery to the motor terminals - a working engine will work.

To check the sensor-switch of the electric fan, disconnecting the wires from the sensor, we connect them together with the ignition on. If the fan works, the sensor is faulty.

Connecting an ohmmeter to the terminals of the sensor and lowering it to the length of the thread in the water, we measure the temperature on and off the sensor with a thermometer. To do this, we heat the water almost to a boil, and then control the cooling. For a working sensor, the temperature characteristic should not differ from the above.